In the world of fiber optic systems, coupling efficiency, beam shaping, and precise alignment are often the bottlenecks dictating overall system performance. That’s where tapered lensed fiber comes into play — a specialized optical component engineered to merge focusing functionality with fiber geometry. In this article, we’ll explore what makes tapered lensed fibers indispensable, how they’re made, practical applications, and what to look for when sourcing them.

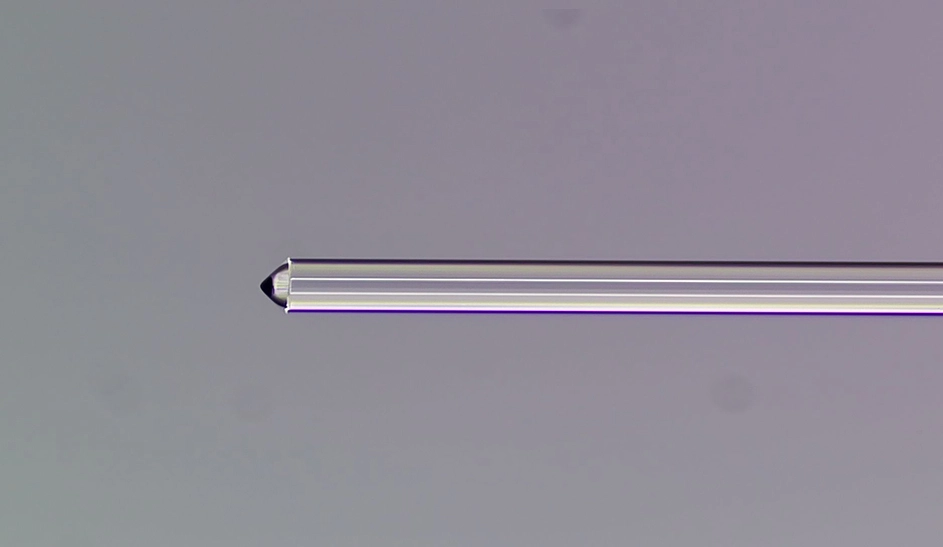

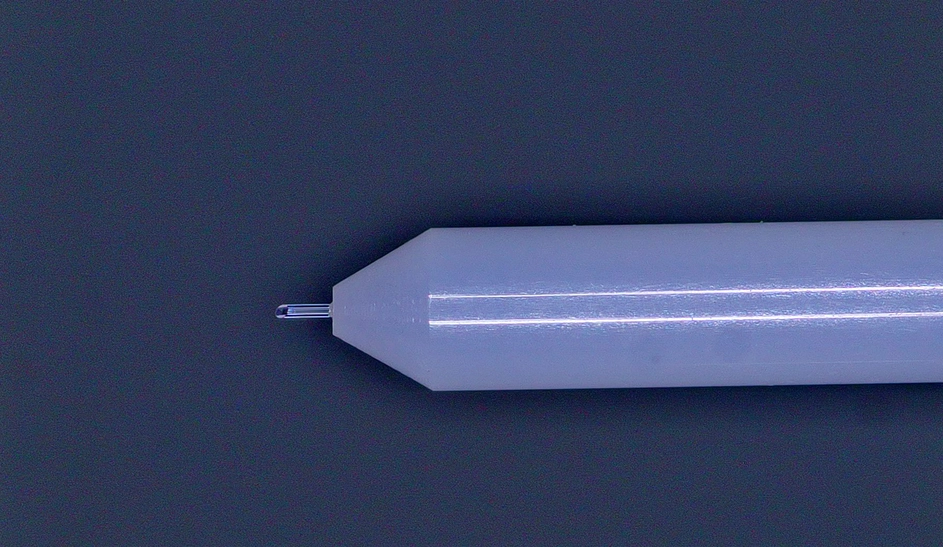

A tapered lensed fiber is a fiber whose endface is modified—via laser shaping or precision polishing—to function as both a taper (narrowing) and a lens. This design allows the fiber to focus or reshape the emitted light, improving coupling into photodiodes, waveguides, or other optical modules.

The taper portion gradually changes the fiber diameter to match the mode field diameter of the target device.

The lensed tip functions as a micro lens, creating a focused spot at a designated working distance.

Depending on the method, the lens geometry may be spherical, conical, wedge-shaped, or more complex.

Because of this dual shaping, tapered lensed fibers excel at mode matching and improving coupling efficiency between dissimilar optical components.

Creating high-performance tapered lensed fibers demands tight control over geometry, surface quality, and alignment. Here are the main production techniques and design factors:

Laser shaping is often used for single-mode or polarization-maintaining fibers because it allows very precise curvature and flexibility in lens profiles.

Polishing / mechanical shaping is more common for multimode fibers. The end is polished with a defined radius and taper angle.

You must match the focused spot diameter to your target component (e.g. waveguide core size, photodiode area).

Working distance (distance from the lens to the focus point) is a key design parameter. Some lensed fibers focus within tens of micrometers.

To reduce Fresnel reflections and insertion loss, AR coatings on the lensed tip are often applied.

Protective coatings or encapsulation help prevent damage to delicate lens surfaces.

These fibers can be made from single-mode (SM), multimode (MM), or polarization-maintaining (PM) fiber substrates.

The substrate’s refractive index profile, core/cladding design, and fiber geometry influence how the taper and lens perform.

After fabrication, the fiber lens is often characterized using beam profiling, spot-size measurement, back-reflection tests, and far-field / near-field scanning.

Ensuring concentricity and surface smoothness is critical to minimize loss and aberrations.

Tapered lensed fibers are used across many photonic and optoelectronic fields. Below are key areas where they shine:

Improving light coupling between optical fibers and on-chip waveguides is a major challenge due to mode mismatch. Tapered lensed fibers help reduce coupling loss by matching mode fields and focusing light precisely.

Laser diodes often emit diverging beams; focusing that light into a fiber requires careful shaping. Tapered lensed fibers are widely used to couple diode light efficiently into fiber.

In sensors or endoscopes, compact optical probes are needed. Lensed fiber probes can deliver or collect light precisely at micro-scales.

Arrays of lensed fibers can address multiple channels or cores, enabling parallel coupling (e.g. in arrayed PICs).

By tapering fiber geometry, some designs manage power scaling and nonlinear effects. For instance, tapered double-clad fibers form the backbone of certain high-power fiber amplifier designs.

When evaluating or procuring tapered lensed fibers for your optical setup, keep these considerations in mind:

Target Spot & Mode Matching

Ensure the lens focuses light into a spot size and mode that matches your target (waveguide, detector, etc.).

Working Distance & Lens Geometry

Your device layout often dictates how far from the fiber tip your focused spot should be. Verify the working distance suits your mechanical constraints.

Loss & Return Loss

Ask for insertion loss, return loss, and back reflection specs. AR coatings or optimized lens curvature can reduce unwanted reflection.

Fiber Type & Compatibility

Confirm that the fiber’s core/cladding dimensions, NA (numerical aperture), and fiber type (SM / MM / PM) align with your system requirements.

Mechanical Robustness

The lensed tip is delicate. Encapsulated or protective designs mitigate damage risk during handling, packaging, or environmental exposure.

Customization & Manufacturer Capability

Many projects require custom lens shapes (aspherical, wedge, chisel, etc.). Choose suppliers who support custom design, testing, and quality control.

Call us on:

Call us on:  Email Us:

Email Us:  2F, BLDG 6, #168, Changshan IZ, Liulian, Pingdi, Longgang District, Shenzhen, China

2F, BLDG 6, #168, Changshan IZ, Liulian, Pingdi, Longgang District, Shenzhen, China