Unlock superior optical alignment and transmission with high-quality lensed fiber coupling, engineered for peak performance in demanding applications.

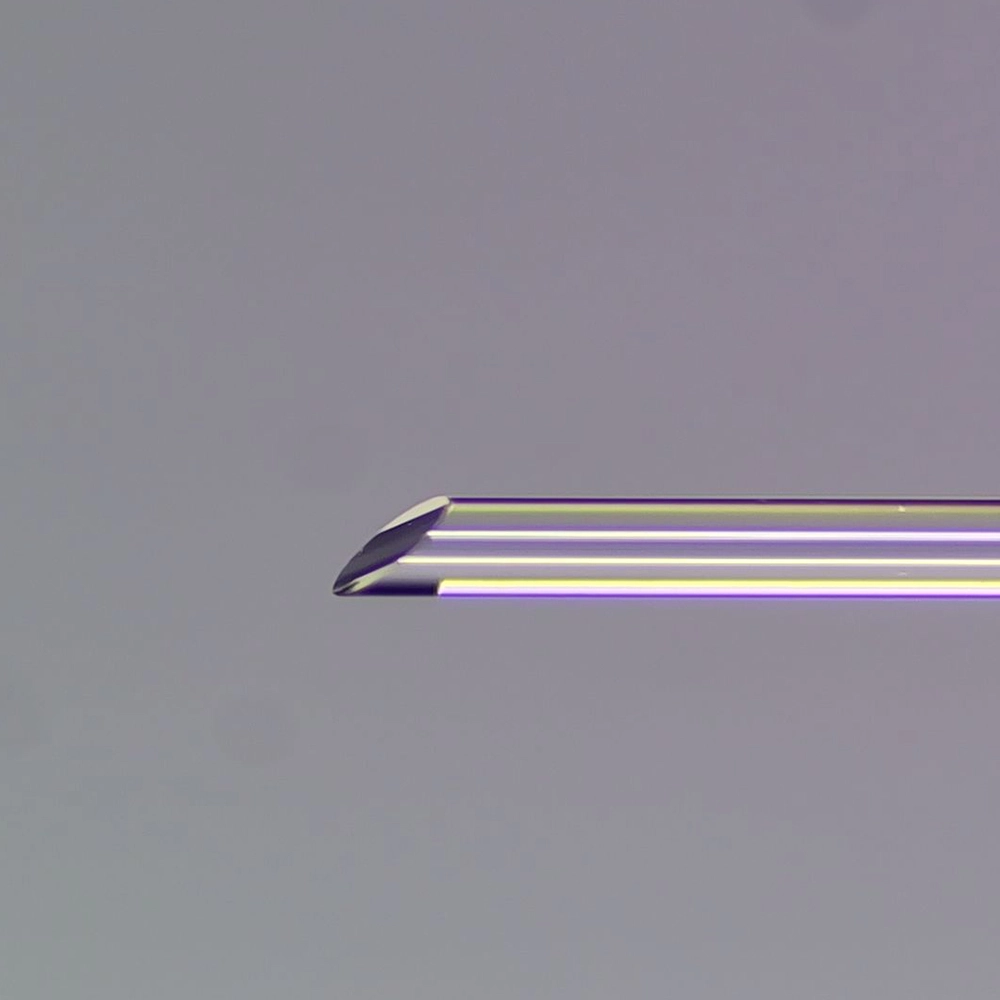

Lensed fiber coupling refers to the technique of modifying the tip of an optical fiber so that it behaves like a tiny lens — enabling light to be efficiently focused, directed, or matched into another optical device or fiber. The specially shaped tip (such as spherical, conical, wedge or biconical) essentially forms a lens at the end of the fiber, which transforms and optimises the beam profile for coupling.

Because standard fiber end-faces emit a diverging beam, without a lens the optical mode from the fiber may not align well with the receiving optics or fibre core. Lensed fiber coupling overcomes this by shrinking the spot size, extending the working distance, improving mode-matching and reducing alignment sensitivity.

In short, lensed fiber coupling turns a simple fiber end-face into an integrated micro-optical interface — enabling more precise, higher-efficiency connections in optical systems.

When you choose a lensed fiber coupling approach, you unlock a series of benefits that can make a meaningful difference in system performance:

Higher coupling efficiency: By optimising the beam shape and mode matching, the amount of light transferred between fibers or into modules is maximised.

Improved alignment tolerance & working distance: Many lensed fibers offer a longer working distance and wider tolerances for positioning, reducing assembly cost and complexity.

Compact optical footprint: The lens is integrated directly on the fiber tip, which simplifies the optical path and avoids bulky external optics.

Better signal integrity and lower losses: For single-mode fibers especially, matching the mode field diameter and reducing divergence means lower insertion loss and improved coupling stability.

Enhanced application versatility: From telecom modules and fiber-coupled laser diodes, to microscopy, spectroscopy and medical probes — lensed fiber coupling delivers for a wide spectrum of uses.

At the core of effective lensed fiber coupling is precise manufacturing, custom tip shaping and coating control. Here’s how the process works:

Fiber tip shaping – We carefully polish, grind or taper the fiber end into the desired lens geometry: spherical, conical, wedge, biconical or angle-polished. Each geometry is chosen based on the beam profile and target application.

Mode-matching optimisation – For single-mode fibers and tight coupling into waveguides or laser diodes, the geometry is designed to match the mode field diameter, numerical aperture and optical path of the target device.

Anti-reflection (AR) coating or metallisation – To minimise back-reflection, improve transmission and support high-power applications, the lensed tip can be coated or metallised.

Quality and reliability testing – Since coupling losses and alignment errors can dominate system performance, we ensure each lensed fiber meets strict optical and mechanical criteria.

With this engineering approach, the outcome is reliable lensed fiber coupling that integrates seamlessly into high-performance optical modules — whether it is a fiber-coupled laser diode, photonic chip interface or precision sensor.

Here are typical use-cases where lensed fiber coupling delivers real value:

Telecom & data-centre optics: Efficient coupling into small-core fibres or photonic integrated circuits (PICs) is critical for high-speed data links. Lensed fibers make this happen with lower losses and better alignment tolerance.

Fiber-coupled laser diodes and amplifiers: Whether you’re pumping fiber lasers or delivering laser output via fibre, lensed fiber coupling ensures efficient light transfer and minimal losses.

Biomedical imaging & spectroscopy: In applications like endoscopy or optical coherence tomography (OCT), compact, high-precision light delivery via lensed fibers improves resolution and signal integrity.

Industrial vision and laser processing: For systems that require precise light delivery, beam shaping or coupling into optical sensors, lensed fiber coupling provides robust, reproducible interfaces.

Quantum and sensor technologies: Microsystems and integrated photonic devices often require tight coupling into tiny waveguide structures — an area where lensed fiber coupling excels.

Choosing the right lensed fiber coupling solution means partnering with a manufacturer that understands optical design, mode-matching and high precision fabrication. When done correctly, you gain a coupling interface that enhances performance, simplifies assembly and supports advanced optical systems reliably.

Call us on:

Call us on:  Email Us:

Email Us:  2F, BLDG 6, #168, Changshan IZ, Liulian, Pingdi, Longgang District, Shenzhen, China

2F, BLDG 6, #168, Changshan IZ, Liulian, Pingdi, Longgang District, Shenzhen, China